- Monday 8:00AM - 5:30PM

- Tuesday 8:00AM - 5:30PM

- Wednesday 8:00AM - 5:30PM

- Thursday 8:00AM - 5:30PM

- Friday 8:00AM - 5:30PM

- Saturday 8:00AM - 12:00PM

- Sunday Closed

2025 McHale 991 LB Single Dispenser Linkage Wrapper

991 LB Single Dispenser Linkage WrapperMcHale’s round bale wrapper range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly. Farmers and contractors all over the world are under pressure to reduce costs and increase output. To help with this, McHale concentrate on features like the patented hydraulic ground supported bale damper system, patented high-speed transfer system, patented tip rollers, hydraulically operated cut & hold system, 750mm dispensers and high specification components. These features ensure long working life, reliability and a machine rugged enough to handle the toughest crops, heaviest bales and roughest ground conditions. |

|

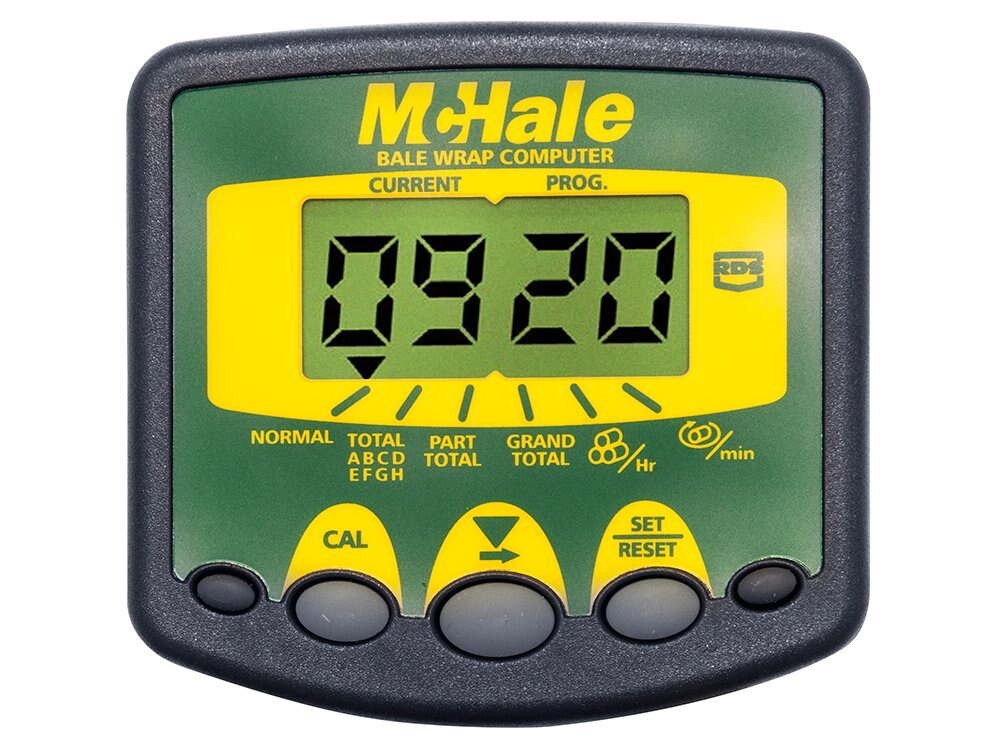

The McHale 991 L range of linkage round bale wrappers is the first choice for farmers and contractors who are interested in wrapping bales at the storage site. The 991 L range offers the perfect blend of tried and tested technology with solid construction and reliable performance. There are three models in the 991 linkage round bale wrapper range. The 991 LB is a manually operated machine where four individual levers control all wrapping functions. Powered by either a tractor or an independent power pack, the 991 LB control valve can either be mounted beside the dispenser post or just inside the tractor cab. The control unit measures the revolutions per minute and monitors the number of layers as they are being applied to the bale. The control unit enables the operator to change the number of film layers and store bale totals from different jobs. |

McHale 991 LB Single Dispenser Linkage WrapperWatch the video for the McHale 991 LB, a manually operated machine where four individual levers control all wrapping functions. |

| 750mm aluminum dispenser | Consistent film stretch, which maximises film usage | Quick Fit Dispenser |

| Hydraulically Operated Cut & Hold | A smooth wrapping seal is guaranteed as the machine delivers a 50% overlap | Wrapping table is constructed of four heavy-duty endless belts, which ensure smooth and consistent bale rotation |

| Transport Length | 2.8 m (9’2″) |

| Transport Width | 1.65 m (5’5″) |

| Transport Height | 1.94 m (6’4″) |

| Height to Top of Rollers | 0.83 m (2’9″) |

| Weight (unladen) | 800 kg (1764 lbs) |

| Bale Size | 1.52 m (3’3″-5′) |

| Aluminum Dispensers | 1 x 750 mm Optional 500 mm Kit |

| Film Stretch | 70% Standard 55% Optional |

| Wrapping Speed (up to) | 30 rotations/min |

| Wrapping System | Turntable |

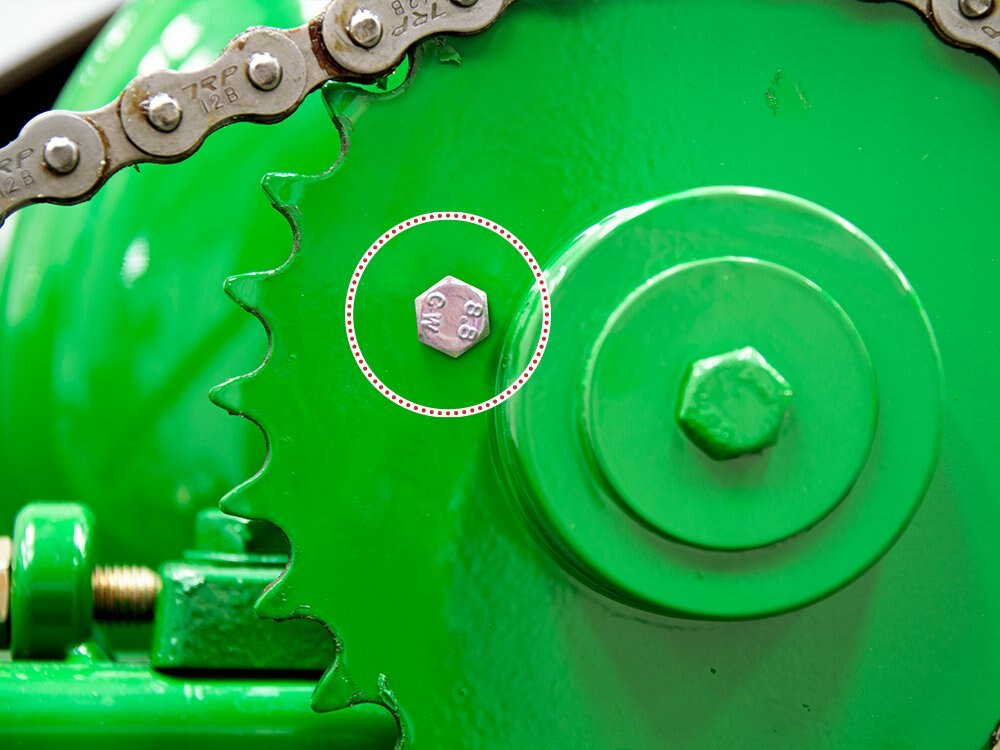

| Protection Mechanism | Shear Bolt |

|

Lift Capacity

@ 170 bar |

N/A |

| Number of Knives | 15 |

| Theoretical Chop Length | 65mm |

| Knife Protection | Hydraulic |

| Knife Deactivation | Hydraulic from Cab |

| Unblocking System | Drop Floor |

| Road Lights | N/A |

| Greasing Points | 11 |

| Wheel Dimensions | N/A |

| Axle | N/A |

| Attachment to Tractor | 3 Point Linkage |

| Min. Hydraulic Requirements | 20 l/min @ 180 bar |

| Hydraulic Connections | 2 x 1/2″ QR’s Open or Closed Centre |

| Electrical Requirements | 12v, 7A supply |

| Minimum hp Requirement | 45 kW / 60 hp |

| Name | Link |

| Download Product PDF | Download |