- Monday 8:00AM - 5:30PM

- Tuesday 8:00AM - 5:30PM

- Wednesday 8:00AM - 5:30PM

- Thursday 8:00AM - 5:30PM

- Friday 8:00AM - 5:30PM

- Saturday 8:00AM - 12:00PM

- Sunday Closed

2025 McHale 998 - Square Bale Wrapper

998 - Square Bale WrappeThe McHale Square Bale Wrapper Range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly, while delivering the highest output and reliability through the use of quality components, precision engineering and our patented oscillating rollers and patented roller angle measuring system. Designed to provide greater operator comfort and flexibility whilst maximising output and reducing maintenance intervals, the McHale 998 range has become renowned and respected worldwide for bringing square bale wrapping to a new level. |

|

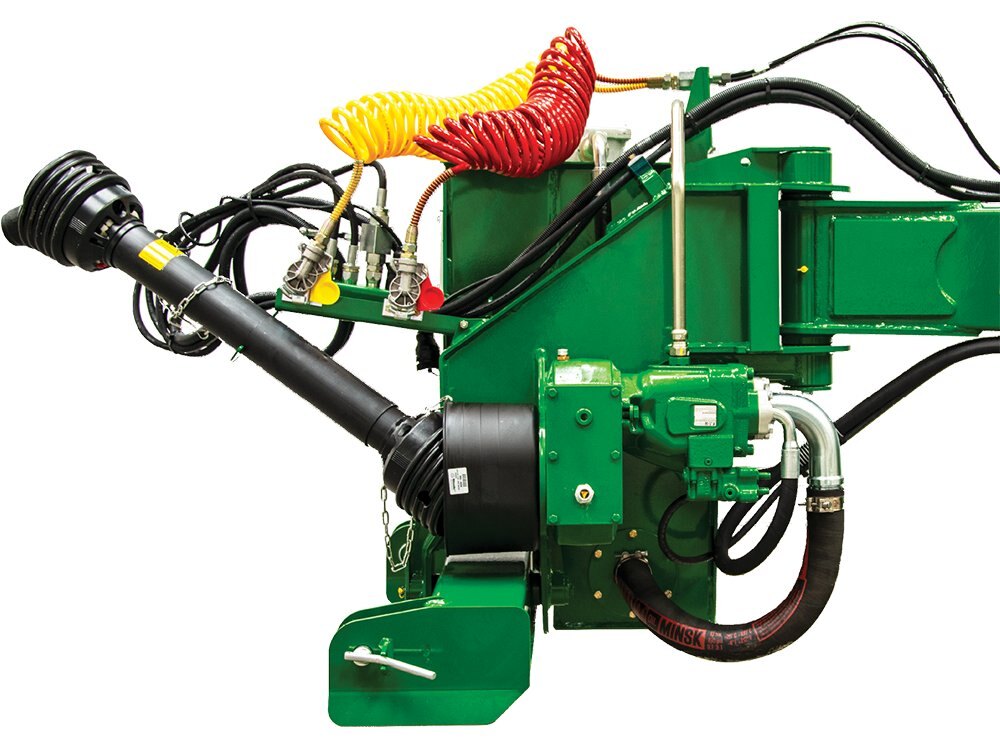

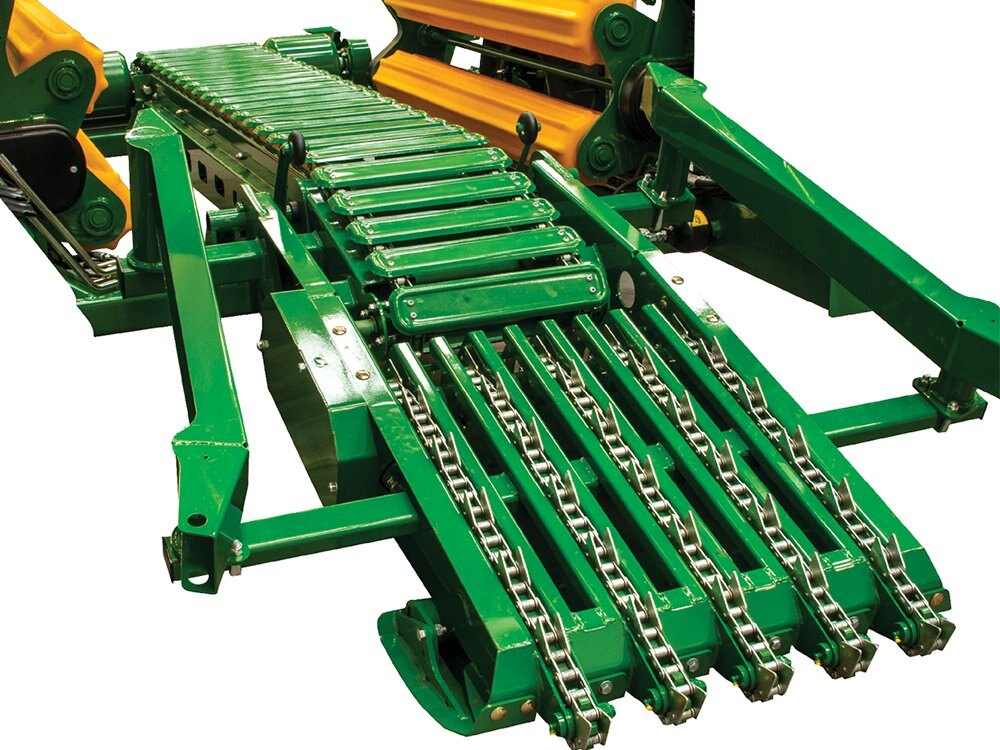

The 998 square bale wrapper is a high-output machine packed with features including a fully integrated, PTO driven, load sensing hydraulics system, conveyor loading with fast positioning of the square bale into the bale wrapping position, hydraulically operated cut & tie system, auto square bale levelling and a two point linkage mounted swivel headstock. It is equipped with two patents;

|

McHale 998 – Square Bale WrapperWatch the video for the 998 square bale wrapper, a high-output machine packed with features including a fully integrated, PTO driven, load sensing hydraulics system, conveyor loading with fast positioning of the square bale into the bale wrapping position, hydraulically operated cut & tie system, auto square bale levelling and a two point linkage mounted swivel headstock. |

| Fully Automatic Electronic Control | In-cab Control of Bale Size and Film Layer |

| PTO Driven Load Sensing Hydraulics | Hydraulic Drawbar Movement |

| Continuous Cycle Function (Load / Wrap / Drop Bale) | Patented Oscillating Rollers (for Even Wrap Application and Bale Rotation) |

| Automatic Bale Levelling | 2 X 750mm Dispensers |

| Hydraulic Cut & Hold | Film Break Sensors |

| Quick-Fit Dispenser Film Change | Film Replacement Loading Step |

| External Dispenser Index Button | 12 Roll Storage (10 in Storage and 2 in Dispensers) |

| Low Ground Pressure Tyres with Braked Axle | |

| Bale Size (minimum) | Bale Size (maximum) | Max Bale Length |

80cm X 60cm(2’8″ x 2′) |

120cm x 160cm(4′ x 5’3″)* |

2m(6’7″)** |

| Transport Length | 7.3 m (24′) |

| Transport Width | 2.99 m (9′ 8″) |

| Transport Height | 3.69 m (12′ 1″) |

| Weight (Unladen) | 4070 kg (8972 lbs) |

| Bale Sizes | From 80 x 60 cm (2′ 8″ x 2′) to 120 x 160 cm (4′ x 5′ 3″) including double bales: 120 x 70cm (4′ x 2′ 4″) Max bale length 2 m (6′ 7″)* |

| Maximum Wrapping Speed | 25 |

| Film Roll Storage | 12 (10 in storage and 2 in dispensers) |

| Roll Loading Step | Standard |

| External Dispenser Index Button | Standard |

| Tyres | 400/70-20 |

| Axle | 6 Stud Braked |

| Brakes | Hydraulic Brakes (Air brakes – optional) |

| Attachment to Tractor | Cat II/III lower linkage SAE 6 spline PTO shaft |

| PTO Speed | 500-800 RPM |

| Hydraulic Requirement | Continuous – Independent Load Sensing Pump Driven off PTO |

| Hydraulic Connection | 3 x Male ½” Quick Release (1xS.A. 1xD.A.) |

| Control Console | Expert Control Console |

| Wired Handpiece Control | Standard |

| Name | Link |

| Download Product PDF | Download |